Roll slitting is a technique heavily used by Converters (industry). The converter industry normally refers to companies who print, coat and laminate materials. A typical converter is a company that

produces flexible packaging material for packaging food. This may involve purchasing large rolls of plastic film such as biaxially orientated polypropylene (BOPP) which is then printed to the customer's

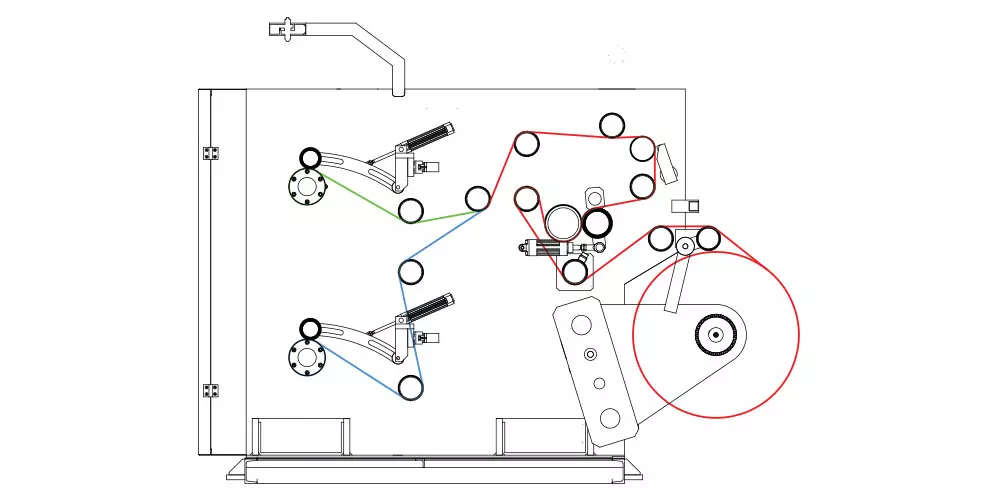

design and coated with cold seal adhesive for use on high speed packaging machines. This material is printed and coated in wide, large diameter rolls for maximum efficiency. The rolls are then slit, using

a slitting machine, into smaller rolls of the size to be used on the packaging machine.

The slitting section has three main options:

-

Razor slitting, which is ideal for thin plastic films – the system is very simple and quick to set. Although the razor blades are of low cost, they need to be

frequently changed to ensure a good quality slit edge.

-

Rotary shear slitting. Male and female circular knives engage to give a scissor cutting effect. This system is used widely on paper, films and foils. Although the

knives take longer to position, they stay sharp longer than razor blades. The setting time can be reduced by using an automatic knife-positioning system

- Crush cut slitting. A male knife runs against an anvil. The system works well with certain materials including non-wovens and foams

With the Finished good like Namkeen Pouch, Rice Bags, Aluminium Pouch, Cement bag,

Non woven rolls, PVC Shrink Labels, sack film, Cereal packaging, Courier bags / security bags, Surface

protection film, Compression packaging pouch and Laminated Pouch Packaging film Products.