- Machine Frame construction of 30mm mild steel plate

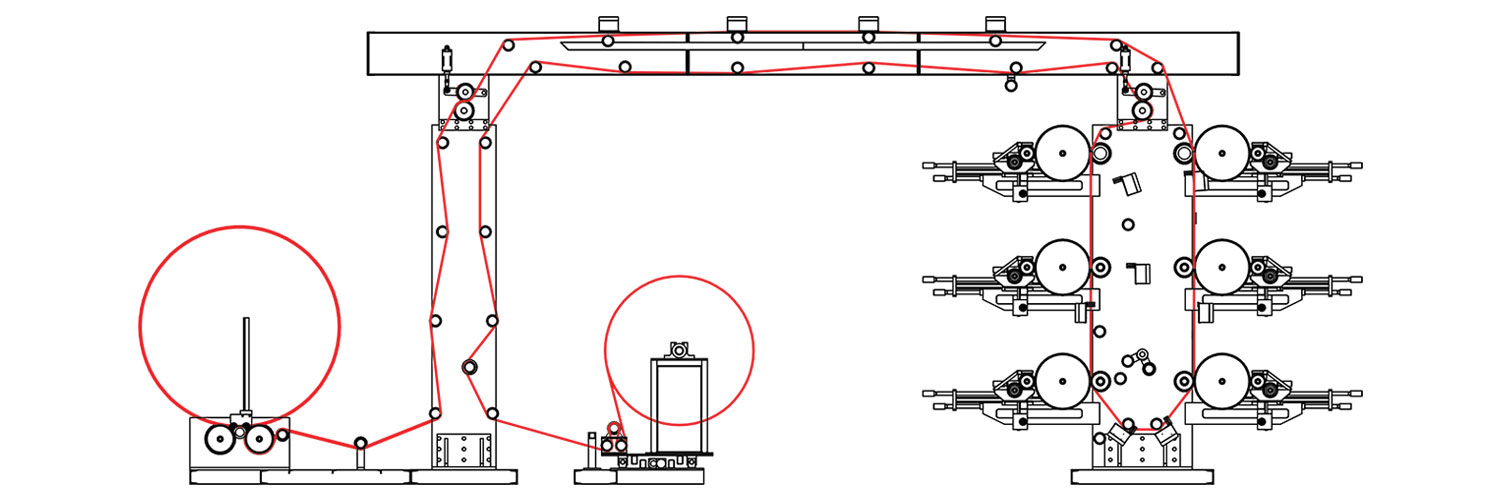

- Simplex/Duplex unwind station with manual spring type brakes

- Simplex/ Duplex rewind station with manual spring type clutch

- Rewind with torque motor and controller

- hafting of 60mm for high load of roll can handle

Nip-Roll

- The system mainly composed of matt chromium plated steel roller AC servo motor and drive, load cells and rubber covered nip roller with pneumatically adjustable pressure